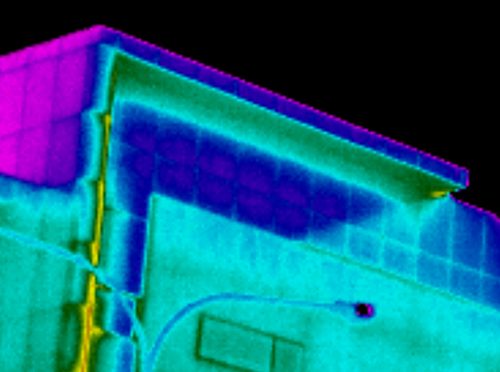

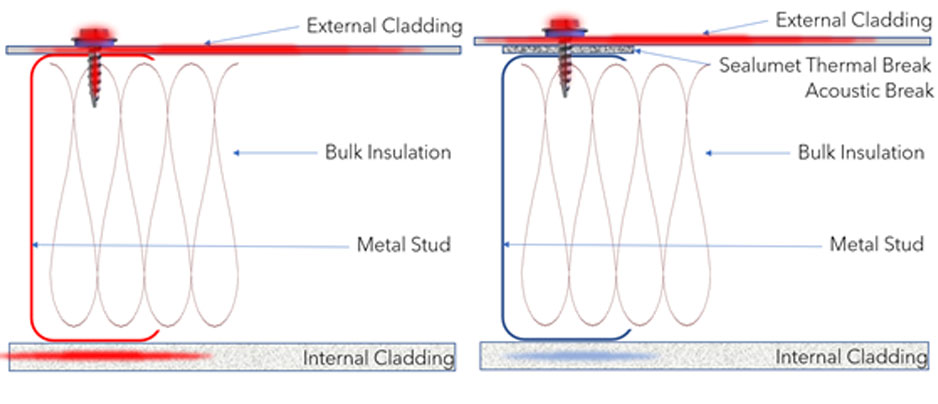

Thermal bridging occurs when two conductive materials are placed in contact against each other within a building assembly or where there exists a discontinuity of insulation.

The resulting conduction of heat energy transferring between these materials can be a major source of energy loss in buildings, leading to lowered of thermal efficiency, higher operating costs due to increased consumption of energy and potential increased costs of asset maintenance.

The simplfied example below shows how heat travels through the building assembly via the structural elements.

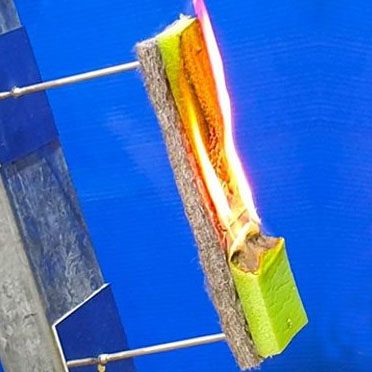

The importance of addressing the issues concerning thermal bridging have long been a concern for regulators who have brought forward a regulatory framework for industry compliance in Australia and New Zealand. This regulatory framework, while addressing the need for materials to meet the required R0.2 (at 23°C) thermal resistance it ignored the fire performance required of these thermal break solutions.

This has caused a major issue for Australian building industry supply chain as well as designers, certifiers and builders.

Unfortunately, many of the materials currently employed as thermal break solutions in Australia are either combustible when tested to AS1530.1 or are cumbersome and difficult to install.

SLS Thermal Break insulation has been tested to meet current NCC standards for both thermal and fire compliance. We have achieved R0.21 (at 8mm thick) in accordance with AS4859.1 and is Classified as Non-Combustible to AS1530.1.

Additional benefits of specifying SLS Thermal Break insulation.

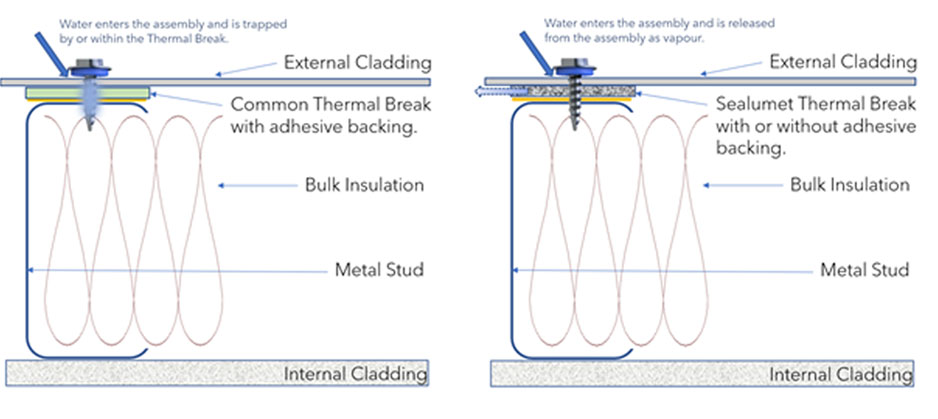

Moisture management

SLS Thermal Break insulation manages moisture in 2 ways. It repels water but allows vapour to pass through itself. It will not allow water to wick or to be absorbed within its structure and as such water cannot be trapped within the assembly.

This is important for two reasons.

- 1) When insulation is wet, thermal resistance is greatly reduced. This will compromise the ability of the insulation to maintain the required R.02 thermal resistance value.

- 2) Wet insulation that retains water around fixings and building elements that will contribute to Corrosion Under Insulation (CUI) and ultimately compromise the structural integrity of the assembly.

Acoustic decoupling.

An added benefit of using SLS Thermal Break insulation is that in decoupling the conductive elements thermally it can also decouple the same conductive elements from sound energy.

Acoustic energy like thermal energy will take the path of least resistance within highly conductive building materials.

This structure-borne noise is an annoyance to building occupants and is often a source of complaint.

Ease of use.

SLS Thermal Break insulation is safe and easy to use.

- Requires no specialised tools or equipment.

- Available in a wide variety of formats from bulk rolls to tapes and pads.

- Can be customised and requires no specialised equipment for installation and use.

- Perfect for either repeating or non-repeating Thermal Bridging requirements.

A customisable solution.

Cut in Australia specifically to meet the particular size, shape and thickness our customers require for their proprietary system.

This includes:

- 8mm, 16mm and 20mm thickness.

- Blankets.

- Rolls.

- Tapes.

- Strips.

- Pads.

- Complex shapes to suit any design and application.

For more information or to talk to an expert, please contact us at salesaus@sealumet.com.