When making decisions based on material selection for fire performance, a good question to ask is:

Do I need this material to just not burn?

Or

Do I need this material to protect lives and infrastructure?

It is now generally accepted that all materials used in building and construction should be non-combustible.

But

Not all materials deemed to be non-combustible are capable of protecting lives and infrastructure.

To define how a material will behave when exposed to fire and ultimately where and when this material can be used in the building envelope, the National Construction Code (NCC) requires Manufactures, Suppliers, Certifiers, and Installers to be able to understand the differences in the test standards and when they are applicable.

A problem occurs, however, in understanding what test is used to support a particular performance requirement of a standard and how this impacts material choice, application and installation.

Sealumet Australia has successfully completed a suite of fire testing of our SRW Rock Mineral Wool range to meet the NCC fire compliance requirements for the Australian and New Zealand markets.

These tests comprise of:

AS/NZ1530 part 1 Test of non-combustibility.

This test provides either a pass or fail result and is used to confirm that the material tested does not contribute to a fire.

SRW rock mineral wool was “not deemed to Combust”: In other words, our material will not burn or contribute to the fire in any way.

Non-Combustibility should be considered as the minimum standard for all building materials. The test cannot however provide enough evidence for use as a passive fire product.

AS/NZ1530 part 3 Test to determine Fire Hazard Properties.

The fire test is used to assess the performance of the material and its reaction to fire by analysing factors such as:

a) Ignitability Index – (rated from 0 to 20, 0 being the best)

SRW rock mineral wool tested as 0

b) Flame Propagation Index (rated from 0 to 10, 0 being the best)

SRW rock mineral wool tested as 0

c) Heat Evolved Index (rated from 0 to 10, 0 being the best)

SRW rock mineral wool tested as 0

d) Smoke Developed Index (rated from 0 to 10, 0 being the best)

SRW rock mineral wool tested as 2

The results of this test are expressed as indices and as such

SRW Rock Mineral Wool achieved 0/0/0/2.

From these indices it can be concluded that SRW rock mineral wool will not ignite, propagate flame, will not release heat upon ignition and releases minimal smoke due to the binder added during manufacture.

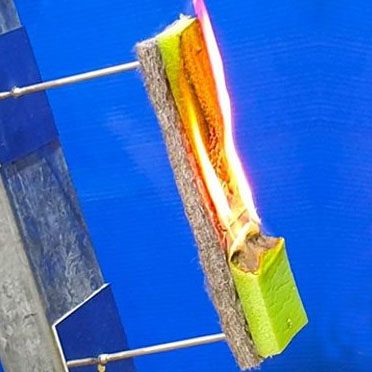

AS/NZ1530 part 4 Test to determine Fire Resistance Level

It is in this test that SRW Rock Mineral Wool stepped ahead of the pack.

The part 4 test is a test of a materials ability to resist the passage of fire for wall elements and penetrations and is expressed as a Fire Resistance Level (FRL) in minutes.

Elements of an FRL are:

- Structural Adequacy: Ability to maintain structural adequacy and load bearing capacity.

Insulation materials generally are not used in the capacity of providing structural support and therefore cannot be tested as such.

For this reason, Structural adequacy is represented by “- – “minutes of performance.

- Integrity: Ability to resist the passage of fire and hot gases.

SRW rock mineral wool tested as 240 minutes for 200mm depth

(Layered and jointed installation).

- Insulation: Ability to maintain temp over the unexposed surface below the specified point.

SRW rock mineral wool tested as 240 minutes for 200mm depth

(Layered and jointed installation).

SRW Rock Mineral Wool achieved an FRL of –/240/240 at 200mm depth, achieved in a layered and jointed application.

In the past many manufacturers and suppliers have successfully tested their materials to AS1503.4.

These tests, however tested only one unbroken piece of insulation.

Sealumet understood the importance of providing the industry with a material that not only conformed to AS1530.4 but did so in a real world “as built” fashion to define the actual performance of our product using actual installation methodology.

In the real-world passive fire insulation is installed in layers and in a linear configuration so why would you test the suitability of your material in any other way?

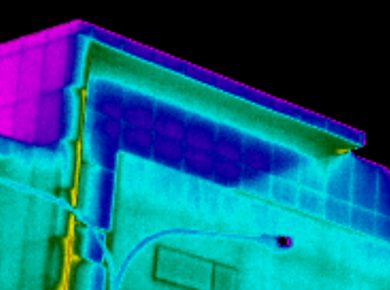

If we are relying on an insulation material to protect lives and infrastructure this material must have a high melting point, high density, be rigid enough to hold itself in position without slumping, and still be able to be compressed into the assembly.

SRW Passive Fire Control Joint Block achieves all of these requirements.