Description

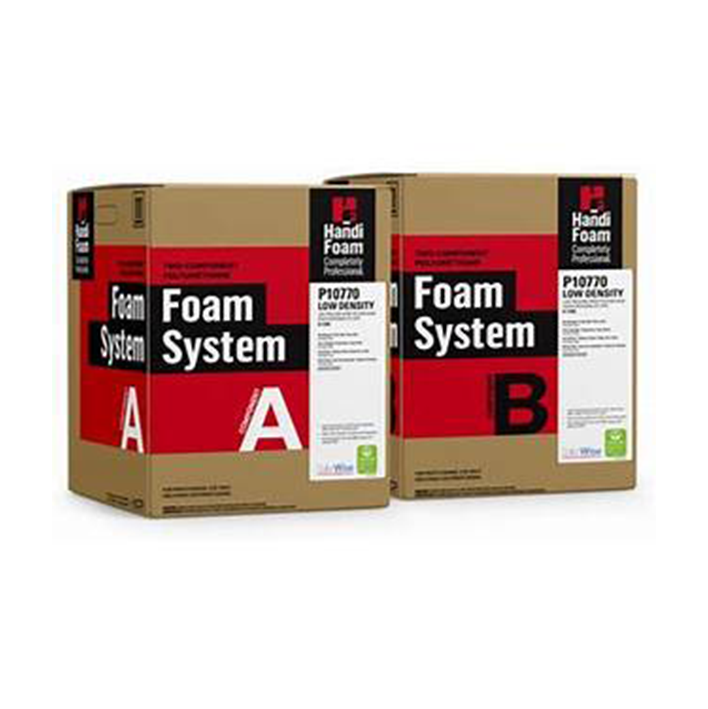

PIR foam is made by mixing a polyol blend with an isocyanate. Adding a blowing agent to this mixture enables the foaming process. The different chains in the molecular web that originate after the reaction give the foam its specific features. When the PUR-joint is more flexible and less brittle, PIR foams exhibit increased fire performance and reduced combustibility and higher service temperature limits compared to PUR. During a fire PIR foam creates a carbon skin that prevents a fast expansion of the fire.